How to Install a Mailbox Post Without Concrete

I am a self-confessed geek, beginner DIY'er, and gardener who enjoys cooking as well as flying drones.

When fence panels blow out or bend, the easiest repair is to put them back in place the way they went in.

By ThrowingStick, CC, via Wikipedia

How to Install Fence Panels in Existing Concrete Posts

We have a fence around our back garden made of concrete fence posts (which look like they'll never move), concrete gravel boards, and wooden fence panels. In a recent storm, seven of the fence panels in our garden were blown out. I looked and looked for some simple instructions on how to get them back in but found so much conflicting advice that I couldn't make head nor tail of it all. I decided to share my own experience here.

When a fence panel is blown out during a storm, it may bend or be thrown to the ground. Check for loose nails or battens and secure them before beginning the replacement.

Before You Start

If your fence panel has blown out, then it's likely that it bent when it blew out. It may have swung half in, half out for a bit or landed hard on the ground at an awkward angle. With all this bending and being thrown around, it's a good idea to check the panel over. Look for loose nails that need hammering back in or battens that may have snapped and need repairing.

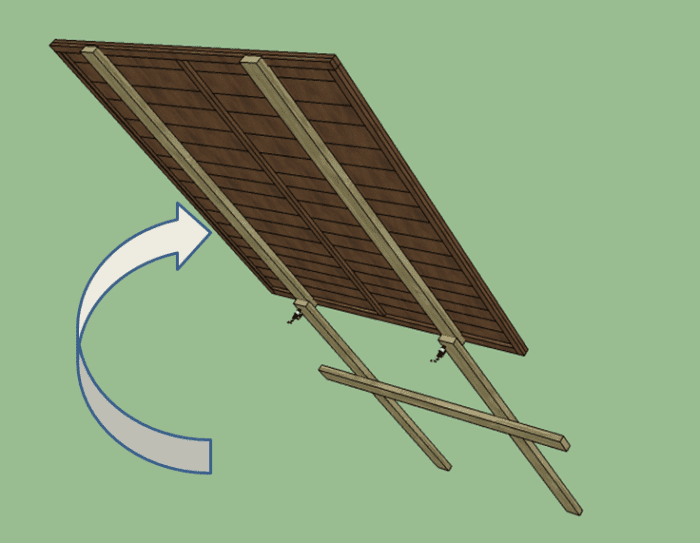

The idea is basically to put the fence panel on the legs so it can be lifted into position before removing the legs and dropping them down. If the fence panel is dry (it hasn't been lying on wet grass for a week), it should be pretty light, making it less awkward to maneuver the panel into position.

Difficulty:

Easy

Materials:

- 5 pieces of sturdy wood around 6' long (a bit longer is fine). 1 should be around 6" wide, the others just need to be strong enough to hold the fence panel.

- Nails

Tools:

- Claw hammer

- Clamps: I bought these clamps specifically for this job, knowing that I would be able to use them for other things afterward. I was very impressed with them. Really quick and easy to put on, tighten up, and take off again—all one-handed.

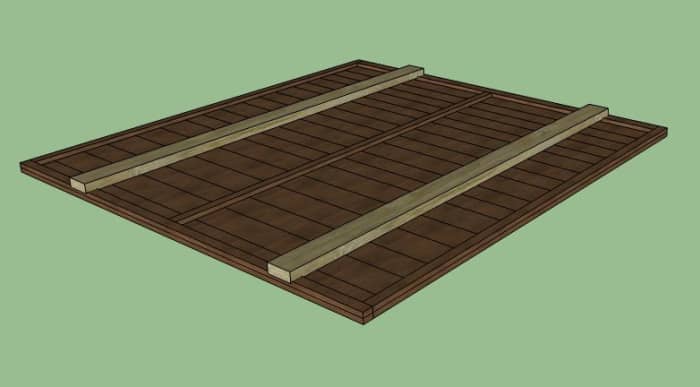

The first step is to reinforce your fence panel. If it's anything like mine, then it will be pretty weak once it's been taken out from between the fence posts on either side. Lay your fence panel on the ground with its "front" facing up.

Step 1: Reinforce Your Fence Panel

If your fence panel is anything like mine, it will be pretty weak once it has been taken out from between the fence posts that support it on either side.

Lay the panel on the ground with the side you want facing your property facing up. Take two of your pieces of wood and position them on top of the panel, running top to bottom about a quarter of the way in from the sides. Nail them in position. (You can use clamps instead, but I only had two clamps, so I used nails for this part).

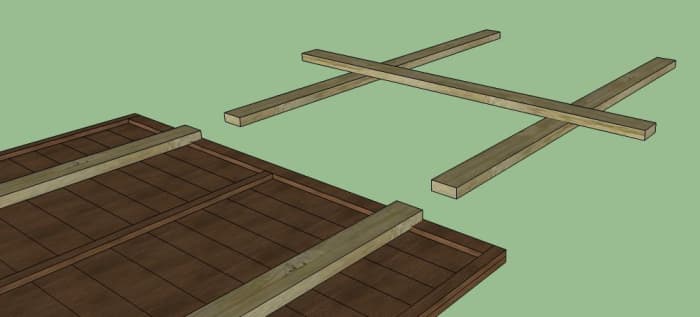

The legs for your panel will end up being an 'H' shape that the panel will sit on. Position two of lengths of wood on the ground parallel to each other, the same distance apart as the two that are nailed in place.

Step 2: Make Legs

Now you want to make some legs for your panel. These will form an H shape, and the panel will sit on top.

Position two of your other lengths of wood on the ground parallel to each other, the same distance apart as the two that are nailed to the panel. Position your 6"-wide length across these two and nail into position. Use at least two nails that are positioned a distance apart at each join. This prevents the wood from twists and makes a more rigid structure.

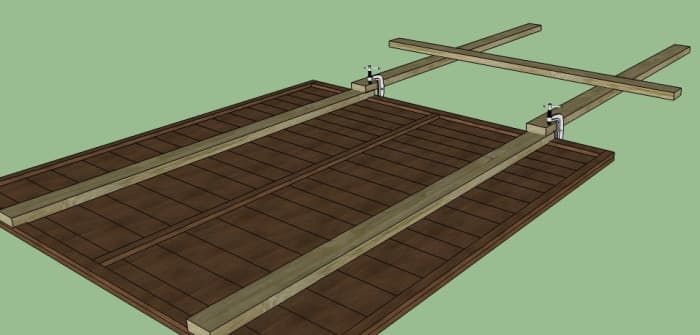

Now clamp the "H" shaped legs to the bottom of the lengths of wood you nailed to the panel. Remember that the side facing up is the side that will be facing you, so be sure the clamps are easy to remove.

Step 3: Clamp the Legs

Now clamp the H-shaped legs to the bottom of the wood lengths you nailed to the panel. Remember, the side facing up is the side facing you once the panel is back in place. Make sure the clamps will be easy to remove from that side.

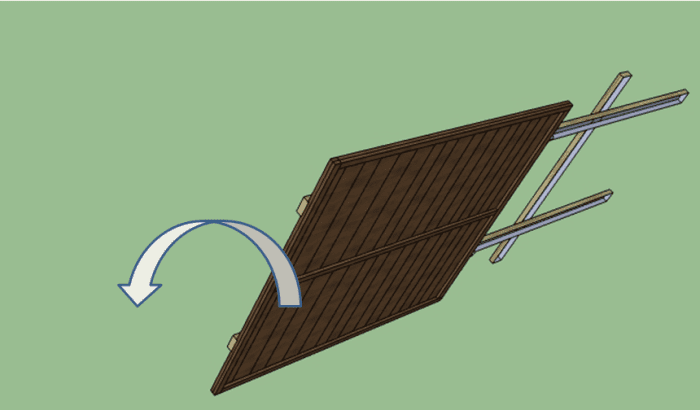

Roll the whole structure over and position the bottom of the legs at the bottom of the empty gap where you want your fence panel to end up.

Step 4: Roll it Over

Roll the whole structure over and position the bottom of the legs at the bottom of the empty gap where you want your fence panel to end up.

Lift the top of the fence panel up over your head and walk forward, lifting the whole structure into a vertical position.

Read More From Dengarden

Step 5: Lift the Structure to Sit Vertically

Lift the top of the panel over your head and walk forward, lifting the whole structure into a vertical position. Once it's fully vertical, you should have a fence panel that's around 12' in the air, with the bottom positioned just below the top of the posts. You may be able to move the top of the posts enough just to push the bottom of the panel between them (the posts will have far more movement at the top than they do at the bottom), or you may need to lift it the last few inches to slot it into position.

Once you've got the bottom of the panel neatly in between the posts, just remove the clamps that are holding the legs on and drop the panel into position. Remove the two lengths of wood that you nailed on in step one, and you're done!

Step 6: Remove Clamps and Lengths of Wood

Once you've got the bottom of the panel neatly in between the posts, just remove the clamps that are holding the legs on and drop the panel into position. Remove the two lengths of wood that you nailed on in step one, and you're done!

Best-Case Scenario

If you're lucky and follow these steps correctly, you'll be able to get your fence panels back in pretty much the same way they came out. The best-case scenario is when you can lift the fence panel up, fit one edge in the groove in the post, and bend the bottom of the panel just enough so you can push the other edge between the posts. Once the bottom is in, then, with a mixture of brute force and gentle persuasion, you should be able to work your way up the panel pushing the rest in.

Our fence is a few years old now, and the panels have started to warp, especially along the bottom edge. This is one reason they blew out so easily. I stood my panels on blocks just high enough to lift the bottom edge higher than the gravel boards. This way, I could rest the panel with one edge, held in the slot in the concrete post, whilst bending the bottom edge to get the other side in.

This technique works best when the panels are wet so that the wood is more likely to bend rather than snap. Not too wet, though, because the wetter they are, the heavier they'll be!

This article is accurate and true to the best of the author's knowledge. Content is for informational or entertainment purposes only and does not substitute for personal counsel or professional advice in business, financial, legal, or technical matters.

Have you found an easy way to replace fence panels?

Rip on October 01, 2018:

Hi Just wanted to say I tried this technique today and it worked thanks for the tip.

Kath on August 16, 2016:

I'm so pleased I found these posts. I'm in my sixties and was widowed recently so like Keith I'm having to think outside the box in order to get jobs like this done on my own (I was very proud of myself when I worked out a way to get the roof box on my car single-handed). Many thanks Phuefi and Keith - I'll be sure to try out your methods when I replace the numerous missing fence panels and posts in my garden!

Keith on May 03, 2016:

Good idea, but I've found a way of doing it on my own (and I'm nearly 80!!)

I clamped (using 2 x G cramps) a decking board horizontally near the top of the posts . In the middle of this I clamped a vertical "ships mast" about 14' high that had a cloths line pulley fixed to the top and a hand winch screwed about 3 ' up from the bottom. I put webbing slings around the fence panels - one at each end and placed them round a hook on the end of the rope that I had wound around the pulley at the top. Wind up the winch and up came the old fence panel - then lowered to the ground and replaced by the new fence panel. Winch up the new fence paned - align the bottom with the grooves on the posts then lower it into the grooves. Pretty simple. I feel like I've invented the wheel... sailors were doing similar things on sailing ships years ago! AND, it didn't cost me a penny as I had all the bits and pieces around the garage and garden. It's amazing how inventive you have to be when you're on your own without the help of a pile of husky builders!

queenofbeauty on March 26, 2014:

Totally awesome!

phuefi (author) on March 22, 2014:

@takkhisa: Glad you like it, I hope it's useful!

Takkhis on March 21, 2014:

Great lens! You are very brilliant and you have shared an excellent tutorial with us. Thanks for doing that.

How to Install a Mailbox Post Without Concrete

Source: https://dengarden.com/landscaping/how-to-replace-a-fence-panel-with-concrete-posts